Cast Pewter Planet Brooch

I made this brooch as an 80th birthday present for my Gran. I came up with the idea of making a brooch involving some kind of planet design. It took quite a few revisions, but eventually I came up with something that I was happy with.

The construction involved CNC milling, silicone mould making and pewter casting to create the finished brooch.

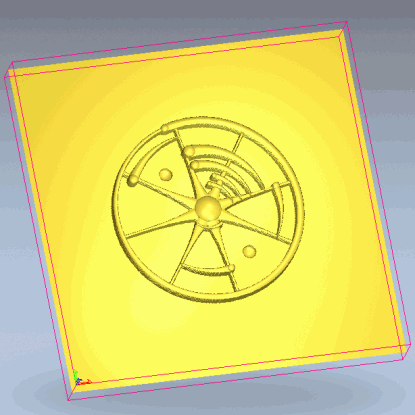

This is what I started with, something a bit planety. After thinking about it for a while I came up with the idea of not just doing random planets, but personalising it so that the planets represented the solar system and not just that, but represented it on the day my Gran was born.

To find the position of the planets I used the Fourmilab Solar System Live site. This lets you enter a date and shows you the relative position of all the planets at that time, perfect.

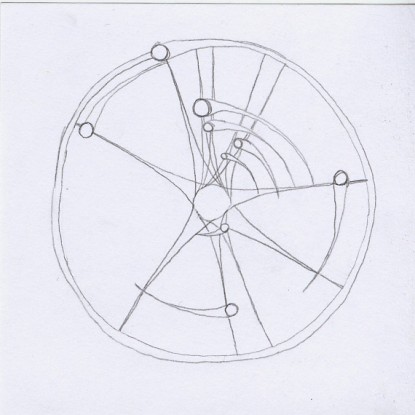

After I had my basic map of the solar system, I had a new problem…coming up with an attractive design. I went through a lot of rough sketches:

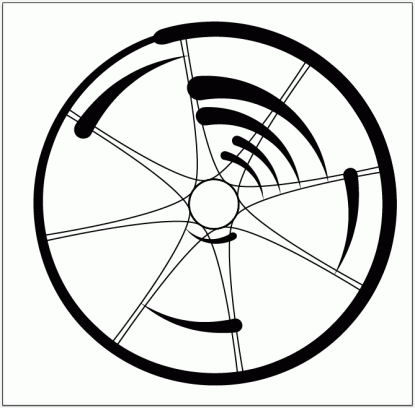

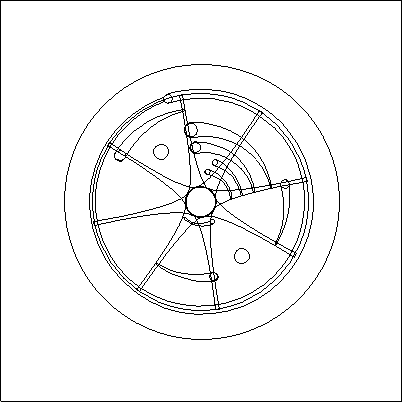

The last design in the sequence is the one I decided to make. Once I’d made my mind up I switched to the computer and cleaned up my paper sketch into a nice vector version. From the vector version I could transfer over to my CNC milling program to set it up for machining. Above is my inital vector image transferred over to my CAD software for machining. The next step was to design a 3D relief. After that I could get the software to generate G-Code toolpaths for my CNC machine. After I’d made the 3D relief I got the G-Code exported and then machined the brooch into a slice of Delrin. When the machining was finished I moved onto the next stage, which involved casting RTV Silicone into the Delrin mould. I’ve used this process before when I was making my Seahorse Earings.The mould came out well, but I ended up having to make some alterations in order to get a good pewter cast. I thought it’d probably be fairly simple…sadly I was wrong. The brooch has a lot of fine channels and small features, these made it difficult to get the pewter to fill the mould well. It took a veeery long time and a fair bit of tinkering to get a cast I was happy with.

The tinkering involved cutting the finest channels in the mould with a scalpel to enlarge them to the point where the pewter would flow reliably. I decided this would be quicker than remaking the Delrin mould multiple times and that I could file/sand off the excess.

The process of casting involved making a wooden back piece so that the pewter would flow into the mould under pressure (the weight of the metal above it). The two wooden halves fit together and have a hole in the center for the pouring. I fitted a metal funnel into the hole just prior to pouring.

Two of the things that I discovered along the way that helped me get a cast I was happy with were that if you dust the silicone mould with talcum powder then that helps the pewter flow much more easily. Secondly, preheating everything I could also helped a lot with getting the pewter to flow into the thinnest sections. I used a heat gun to preheat the silicone mould and a blowtorch to preheat the metal funnel.

In the end I managed to get a cast I was happy with and then it was just a few hours of sanding away from being finished! Easy!

After all the sanding and polishing was done I drilled a small hole in the back behind the sun and attached the pin and clasp from a pin-badge to the back. I used epoxy to glue the pin on and thought that the small hole I’d drilled would give the epoxy something decent to grab onto, making it much less likely to fall off.All in all I think it was worth the effort and the main thing was that my Gran really liked it.